- Energy

Categories:

In February this year, we learned about the European Commission’s strategy for industrial carbon management, which envisages the use of carbon capture and storage (CCUS) technologies to achieve the 2040 climate objectives. These targets are set at a 90% reduction of greenhouse gases compared to 1990 levels. This would allow 280 million tonnes to be withdrawn and stored within 16 years.

Specifically, the Commission has put forward a non-binding proposal that nevertheless serves as an essential guide for the formulation of future policies and legislation that will be binding and necessary to achieve Europe’s proposed goal of climate neutrality by 2050, and to ensure that European industry remains competitive in a global market in transition to a low-carbon economy.

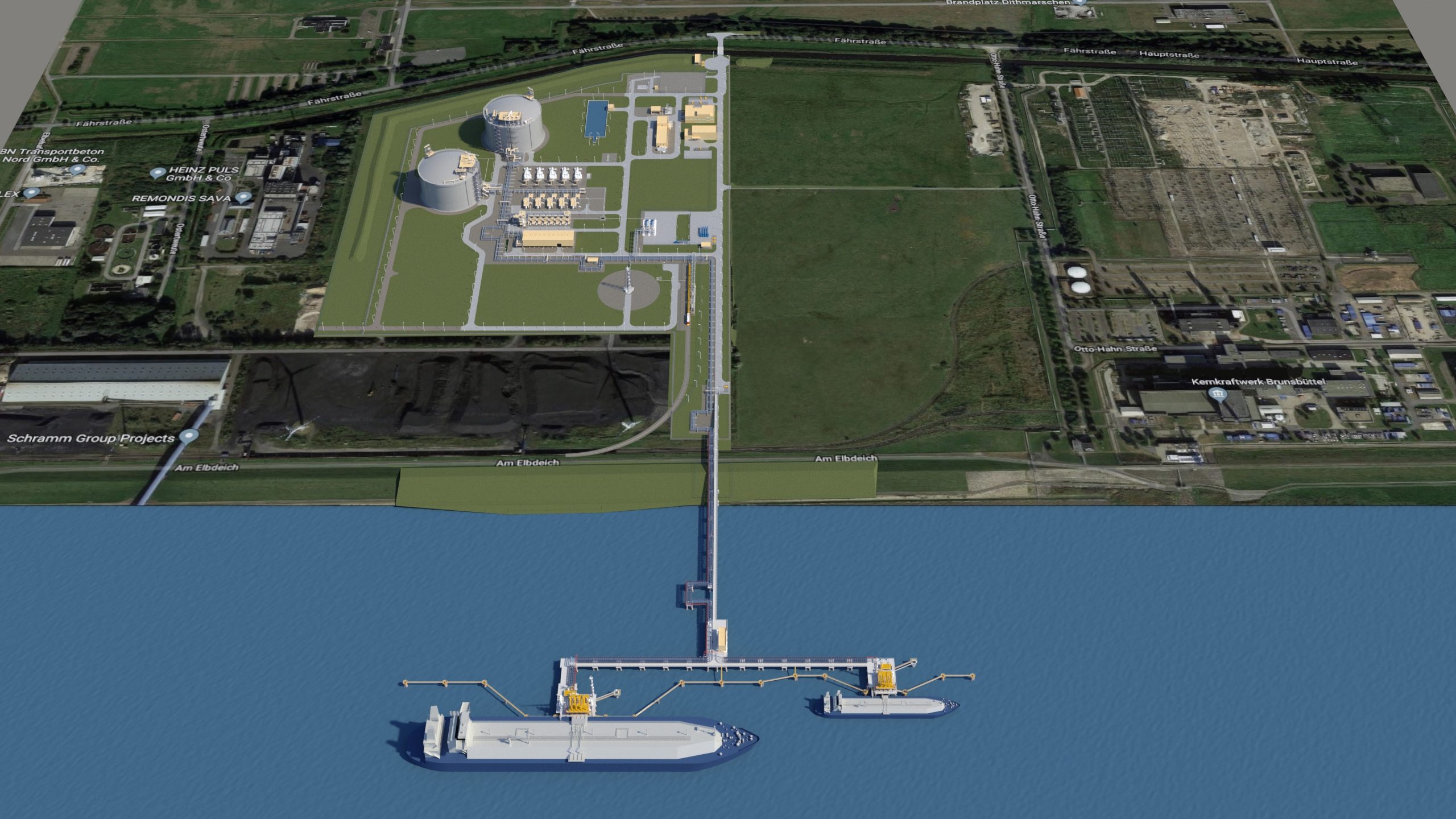

More specifically, this week, the EU passed the Net-Zero Industry Act, the main objective of which is to boost the industrial deployment of “zero-emission” technologies needed to achieve the EU’s climate targets. Among others, the law promotes the development of infrastructure to capture CO2 from large industrial emitters and its safe storage and use in industrial applications.

A project selected as strategic under the Net Zero Industry Act (NZIA) has several advantages that facilitate its implementation, including reduced permitting and approval times, which is crucial for large-scale projects that need to minimise lead time and start-up risks to be viable, such as large industrial CO2 capture projects.

Early CCUS projects and state-of-the-art technology

CO2 capture technology is being applied first and foremost in industrial sectors that are carbon intensive and face greater challenges in reducing their carbon footprint through other strategies. In this respect and until 2030, most capture projects will be carried out mainly with a focus on process emissions, as is the case in the cement industry, whose emissions are mainly due to the calcination process during clinker production. This is a sector from which we can draw interesting lessons and where at least 19 projects are already identified as being under development in Europe.

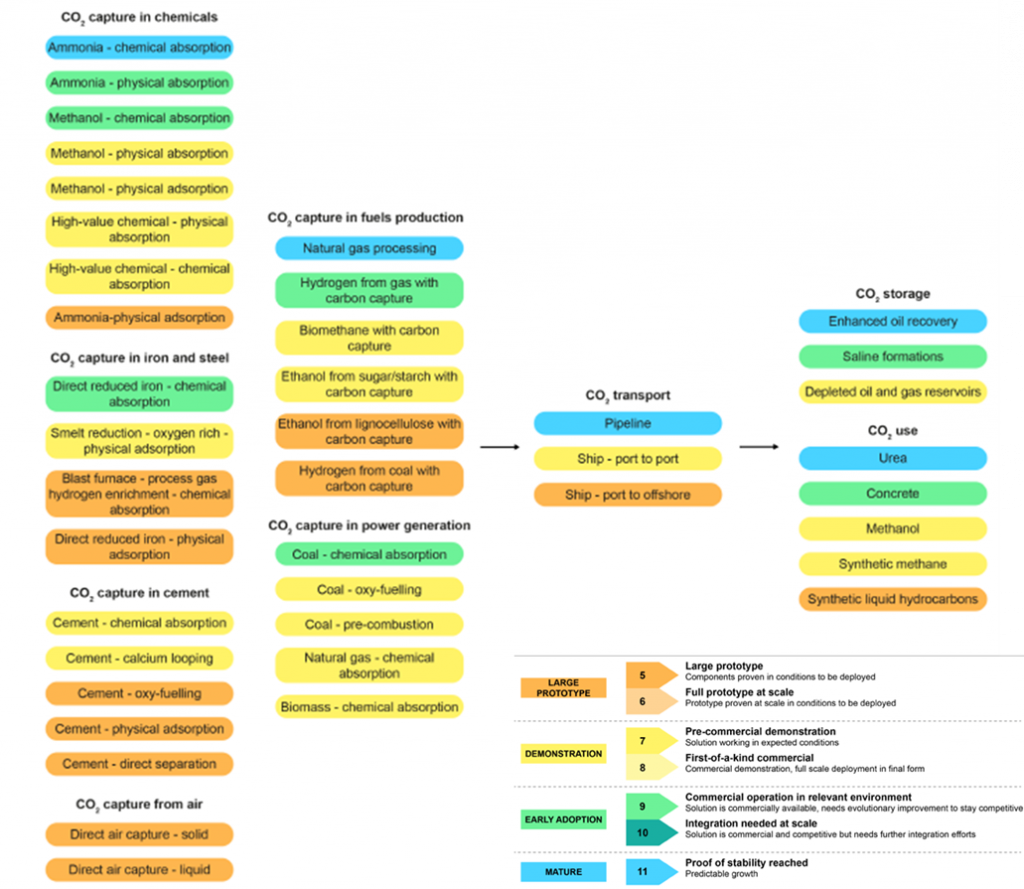

In terms of technology, it should be borne in mind that the success of capture, transport and use or storage of CO2 as a mitigation strategy depends on the availability of technologies at each stage of the process, as well as on the development and expansion of CO2 transport and storage networks. All steps along the value chain must be technologically prepared and developed together for the level of adoption of CCUS to grow.

In this respect, different CCUS technologies are at different levels of maturity. For example, several CO2 capture, transport, use and storage technologies are already being deployed on a large scale, but other technologies, including those promising better performance and lower unit costs, require further development.

It is also important to note, particularly with respect to CO2 capture technologies, that although several mature CO2 capture technologies exist at the component or subsystem level, the integration of such technologies into a commercial-scale plant still needs to be demonstrated.

In order to get an overview, the International Energy Agency (IEA) carried out an analysis that categorises the different existing technologies according to their maturity. We can see, for example, that, broadly speaking, the bulk of the systems are in the prototyping or demonstration phase, but that others are already mature.

Level of readiness of the different technologies that are part of the CCUS value chain © IEA

These carbon-intensive industrial sectors, such as the cement industry, face increasing pressure to reduce their carbon emissions and to comply with increasingly stringent environmental regulations. In this context, carbon sequestration represents a promising solution to address this challenge because of its potentially significant benefits:

- Innovation and competitiveness: adopting technologies such as carbon capture and storage can boost business innovation and competitiveness. Those technologies leading in this field will be best positioned to take advantage of emerging market opportunities and to meet growing demand from customers and regulators for sustainable solutions.

- Regulatory compliance: the tightening of regulations on greenhouse gas emissions means that companies more familiar with carbon capture technologies are better positioned to comply with environmental regulations and avoid potential penalties.

- Carbon footprint reduction: perhaps the most obvious benefit. By capturing and storing the carbon emitted during industrial processes, carbon capture and storage can significantly reduce the carbon footprint. This not only benefits the environment, but also enhances corporate reputation.

The challenge of energy efficiency

It should be noted that CO2 capture technologies are very energy intensive, either thermal or electrical, depending on the type of system. For this reason, one of the most important fields in the implementation of these solutions is energy optimisation and efficiency. To this end, one of the most critical steps in this type of project is to carry out a comprehensive analysis that considers and evaluates all aspects necessary for the efficient integration of the capture technology.

At this point, in addition to more efficient technologies, it may also be necessary to consider the implementation of intelligent energy management systems, waste heat recovery, and the integration of renewable energies. Not surprisingly, these practices are included in the PERTE industrial decarbonisation targets.

In short, carbon capture projects will be crucial in the quest for a more sustainable and responsible industry. Their adoption will not only contribute to the reduction of emissions and compliance with environmental regulations, but will also promote innovation and competitiveness. In an increasingly sustainability-conscious world, carbon capture is emerging as an essential technology for the future of many industries that are difficult to decarbonise, especially in those with emissions derived from the use of carbon as a raw material.

Image by Freepik

- CCS

- Carbon Capture

Tags:

Jesús María Ubillos

Director of engineering projects and proposals in the energy and industrial sectors, with 33 years of experience. He has extensive experience in electrical engineering, thermal generation, and energy storage. His most notable projects include the NOORo III solar thermal plant in Morocco, the EPC of Ence's biomass generation plant in Mérida, and the Zabalgarbi wastewater treatment plant.

About us

About us