- Aerospace

Categories:

Precision and reliability are essential in space missions. These missions represent a significant investment of time and resources, and sometimes must be carried out in unique or difficult-to-replicate conditions – such as the flyby of a comet in the European Space Agency’s Comet Interceptor mission. The importance of these missions is crucial to the development of knowledge about the surrounding Universe (for example, the EUCLID mission, which aims to provide the most comprehensive mapping of the Universe to date) and the immediate environment (the FORUM mission – the ninth of the Earth Explore missions, which aims to explore the Earth’s atmosphere, biosphere, hydrosphere, cryosphere, and interior). Once sent into space, spacecraft must work to the end; they cannot be repaired (except in rare cases).

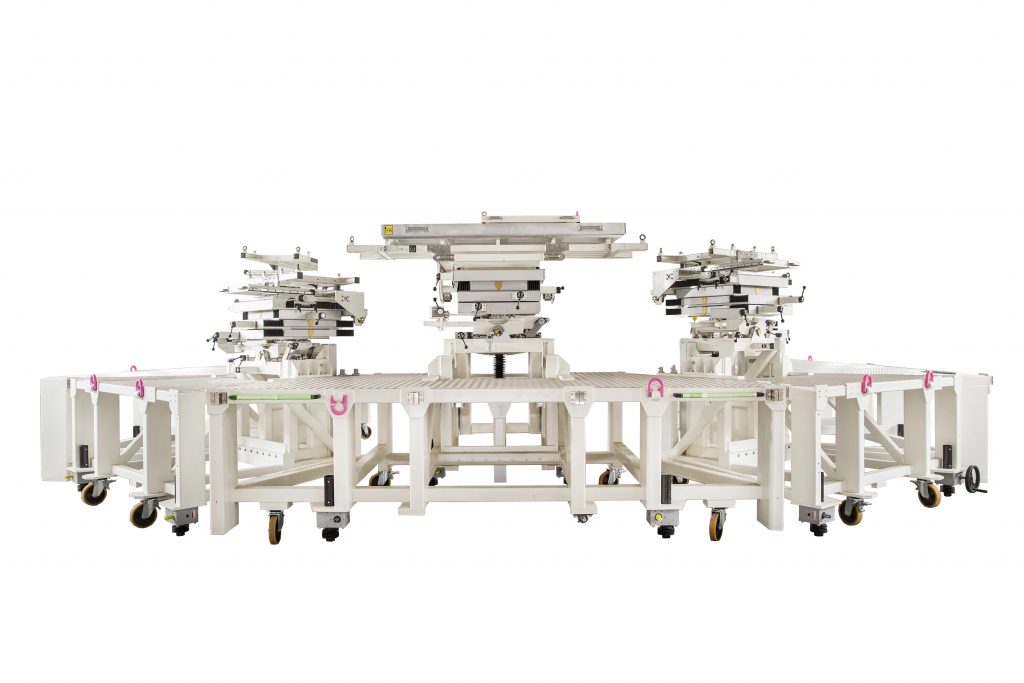

Ground support teams play a key role in ensuring the success and safety of a mission prior to launch. All spacecraft go through a series of well-defined manufacturing, integration, and test phases to verify that all components have been properly manufactured and function correctly. This eliminates errors and verifies the assumptions made during mission design. Thousands of operations are performed as part of this complex and lengthy process, requiring specialized instrumentation such as the MGSE. Mechanical Ground Support Equipment (MGSE) is a specialized set of systems designed to support and protect space missions, from the manufacture of individual components to the successful integration of the spacecraft with the launch system. They include transportation equipment, containers, trolleys, test equipment and adapters, or stabilization frames and racks, etc. Some are impressive in size and weight, up to several tons.

MGSEs are used for a number of critical activities, such as testing, transporting and assembling space equipment prior to launch. This approach allows equipment parameters to be optimized and potential problems to be identified on the ground, reducing the risk of mission failure. The dimensions of these systems vary from a few centimeters to several meters in length and several meters in height. A single MGSEs can be developed in approximately 12-36 months.

MGSEs are one of the most important specializations in the space sector. As part of the EUCLID mission mentioned above, Sener was responsible, among other things, for the design, manufacture, and testing of a set of 13 ground equipment mechanisms supporting the assembly of the main satellite (incidentally, the largest set of this type to be manufactured entirely in Poland to date).

The Comet Interceptor mission, which was mentioned at the beginning, is an initiative of the European Space Agency and JAXA (its Japanese counterpart) to be launched in 2029 to visit, for the first time in the history of space exploration, a pristine comet, i.e. one whose physical and chemical properties have remained unchanged since its origin, never having approached the Sun, of great scientific interest to better understand the origin of our world. The success of this mission will depend, among other things, on 15 MGSE instruments designed and manufactured by Sener in Poland.

In some cases, mechanical ground support equipment must meet extremely high-quality standards, such as cleanliness – the amount of microscopic particles, such as dust or particulates, that can be present on the surface of the equipment. Maintaining such standards means carrying out complex measurement processes and care to obtain the highest quality data. This is one of the most important aspects concerning MGSE for optical instruments and affects the overall design in several areas, such as material selection, ease of cleaning, surface treatment and maintenance. An example of such a project is the FORUM mission, where Sener has to provide the equipment for integration and testing (including thermal vacuum) of the mission’s main instrument. For this project, the cleanliness requirements are very high (ISO-5 class).

For any aerospace engineering enthusiast, it’s easy to marvel at the spectacle and precision of mechanisms sent into space, but equally important are those that serve a supervisory and support function and remain on the ground. Rigorous testing procedures, precise integration of space equipment and satellites, or ensuring the safe transport of delicate parts in production: all of this translates into the subsequent functioning of mechanisms sent into space, minimizing risks and potential losses. A space mission is more than a specialized device sent into space – it is years of design, preparation and even several dozen state-of-the-art technologies responsible for the production and safe and effective operation of a spacecraft.

Przemyslaw Rudzinski

Przemysław Rudzinski has been a member of the Sener team in Poland since 2023. He holds the position of Project Manager for the Comet MGSE and Forum MGSE projects. Previously, he was responsible for other MGSE projects, including the ROSE-L mission. He is also active in organizations related to the development of the space sector, such as the Space Generation Advisory Council (SGAC), where he is responsible for representing SGAC in Poland, and the Polish Space Professionals Association.

About us

About us