- Energy

Categories:

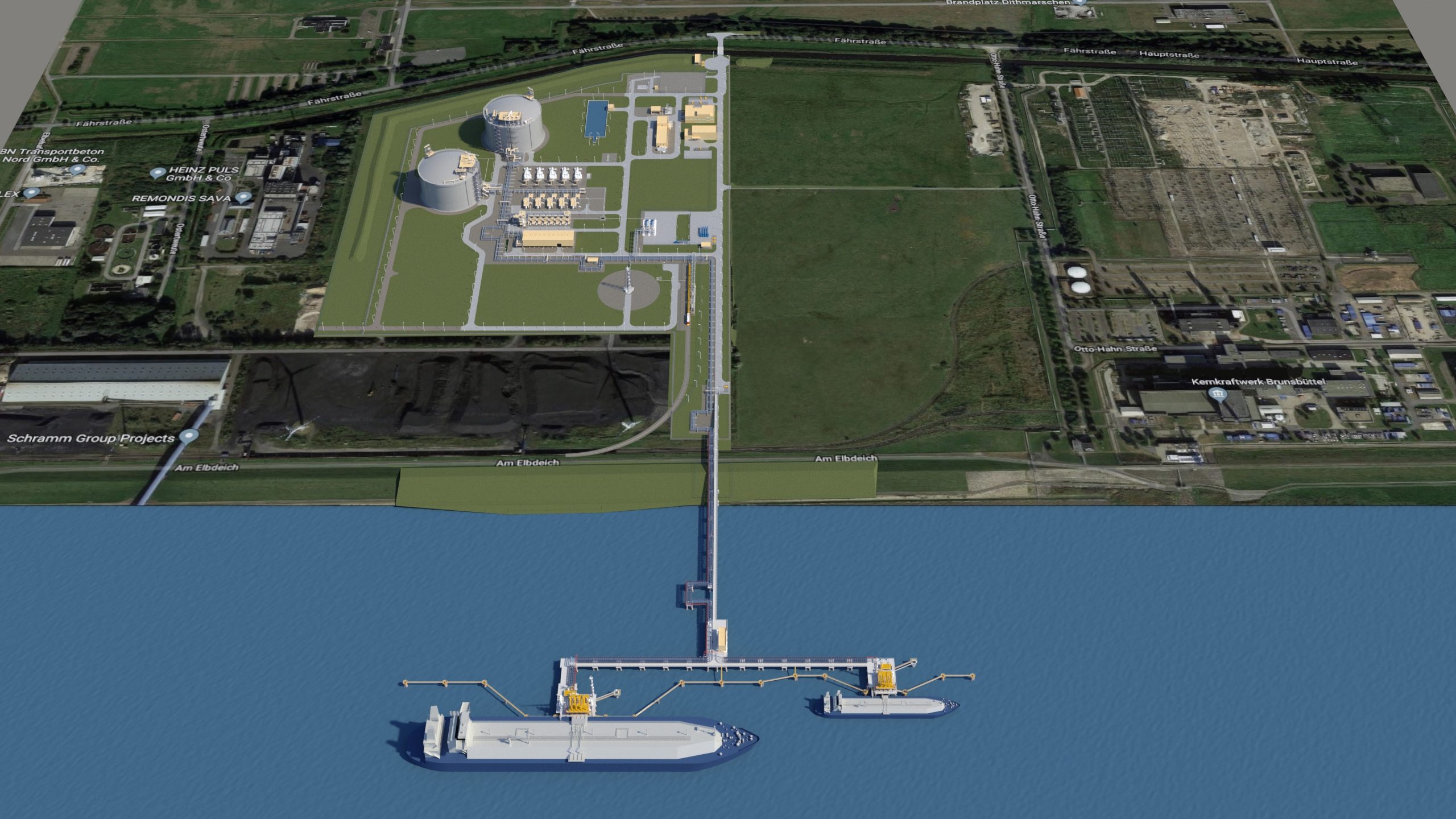

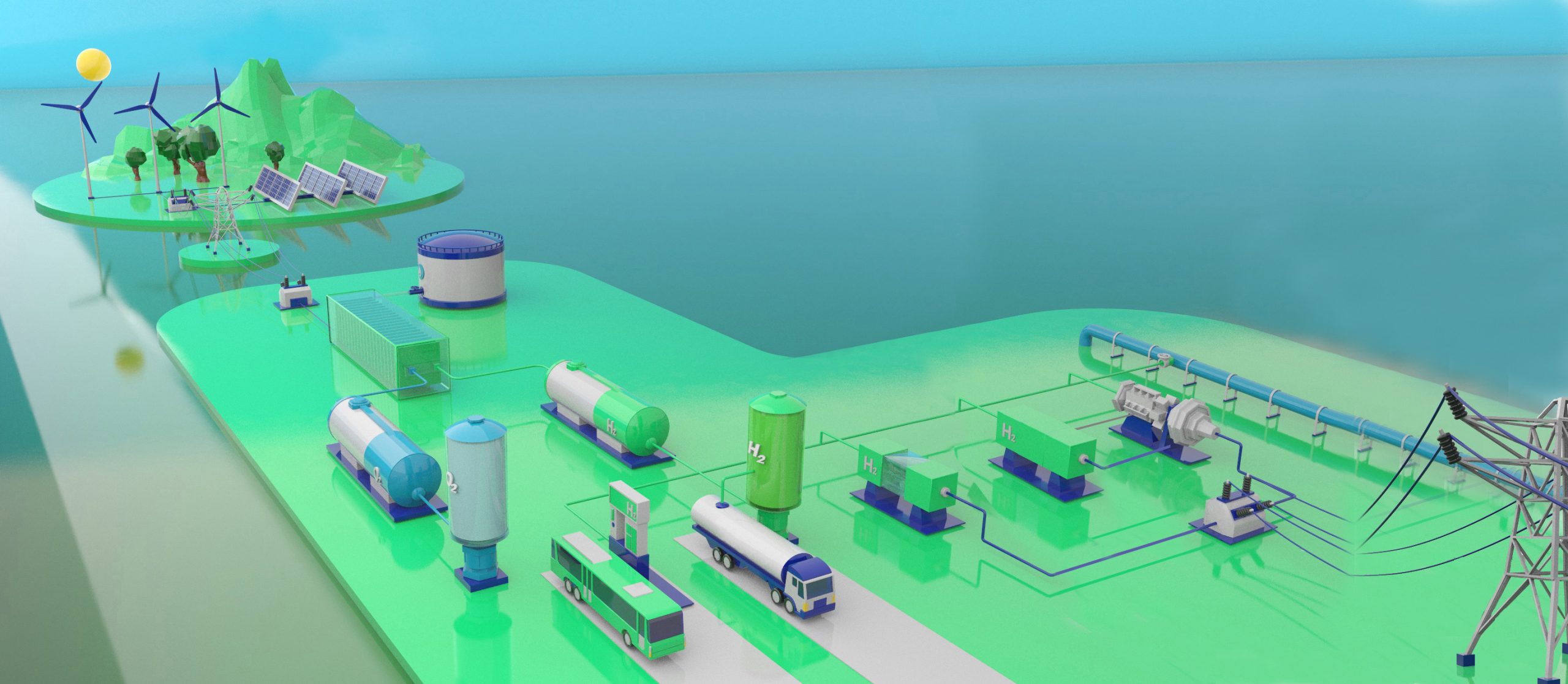

In the current context of energy transition, the design of power generation plants and liquefied natural gas (LNG) storage terminals capable of being converted into infrastructure compatible with cleaner fuels (e.g., hydrogen) has become a growing trend. Comprehensive feasibility studies in this regard are increasingly in demand, with the aim of beginning to plan the transformation of power plants to reduce carbon emissions and adopt the use of cleaner energy sources.

The energy market is undergoing a significant transformation. The growing demand for clean energy and regulatory pressure to reduce emissions are accelerating the adoption of renewable technologies. Furthermore, significant investments are being made by technologists and industrialists to develop and implement new technologies. Green hydrogen, produced from renewable sources, is seen as a key energy vehicle for medium- to long-term decarbonisation.

Such decarbonisation is essential to meeting global climate goals. The transition to cleaner energy sources not only reduces CO₂ emissions but also improves energy security and promotes sustainable economic development.

In an environment where an emerging hydrogen infrastructure is developing, it makes sense to analyse the feasibility of converting energy assets currently running on natural gas to integrate hydrogen as a clean fuel source. Likewise, this energy vector is essential when designing the new fuel import and storage terminals being built in Northern Europe.

Analysing the feasibility of this conversion in specific assets allows for an assessment of the necessary technical modifications, operational impacts, and performance implications of this transition. In this context, consideration must be given to the technical, economic, and environmental feasibility of reusing cryogenic tanks at LNG terminals to store ammonia, as well as the potential transition of power plants, combined cycles, and cogeneration plants that currently burn natural gas to hydrogen.

For example, in the specific case of a three-unit combined cycle plant that Sener worked on, the necessary modifications to the fuel system, combustion pathways, and associated infrastructure were analysed to facilitate the use of hydrogen. Several scenarios were considered, such as a 30% hydrogen blend, 100% hydrogen in one unit, and 100% hydrogen in all units. In any case, it will always be essential to consider national and international regulations to ensure the safe handling of hydrogen.

Technical Studies and Modifications: Case Study and Challenges to Consider

Simulation of the specific asset is essential. For example, in the case of the aforementioned combined cycle plant, a project carried out by Sener’s Energy department, data from the distributed control system (DCS) was used to model the current state of the plant and perform performance simulations with different hydrogen blend percentages.

Six different cases were computed, ranging from 0% to 100% hydrogen blend, analysing performance parameters such as the heat rate of the gas turbine and plant, power generation, and exhaust gas properties.

The conclusion was that cycle performance barely changed and contributed to reducing CO₂ emissions.

Turbine performance is the heart of the equation, defining the starting point for calculating performance. Coordinated work with the turbine operator is therefore essential in these studies. Based on turbine performance, the goal is to find ways to maintain overall plant performance at a similar level while contributing to a significant reduction in CO₂ emissions.

However, the retrofitting of energy infrastructure presents several technical challenges, including:

- Safety: The handling and storage of hydrogen and ammonia involve specific risks that must be managed through robust safety designs and strict protocols.

- Equipment Adaptation: Existing equipment and systems must be adapted or replaced to handle the unique properties of hydrogen and its derivatives.

- Material Compatibility: Hydrogen and ammonia can cause phenomena such as embrittlement, corrosion, etc. in certain materials, requiring careful evaluation and the selection of appropriate materials.

At Sener, we have extensive experience in highly complex engineering projects. Our team of process and materials experts is actively working on energy infrastructure retrofit projects to operate with renewable fuels that will be introduced in the coming years, such as hydrogen, ammonia, and renewable methanol. Without a doubt, the design of innovative solutions that help ensure the safety and efficiency of these operations in the future is key to the transition to a cleaner energy future.

Nora Castañeda

Hydrogen Business Manager

More than 20 years of experience creating innovative engineering solutions, executing turnkey projects, seeking alliances and creating new businesses, fundamentally in the world of Energy, focusing on renewable and sustainable responses, hybridizing technologies and pioneering ideas.

About us

About us