According to the World Economic Forum, 5 of the 10 greatest risks we will face in 10 years’ time, including 4 of the top 5, are environmental. From extreme weather events and increased pollution, to the loss of biodiversity and the scarcity of natural resources, society is facing challenges with a global impact that are forcing companies and governments to adopt a mindset and agenda whose goal is to decarbonize the economy.

Against this backdrop, the energy transition is, of course, a priority for the European Union, with wind power being one of the main sources that is being promoted. In fact, the Commission itself has proposed the target of reaching 60 and 300 gigawatts of installed power by 2030 and 2050, respectively. Spain ranks fifth in the world in terms of onshore windpower generation, and steps are currently being taken to promote its marine equivalent, and especially floating wind power.

In the specific case of Spain, it has more than 6,000 kilometers of coastline, but the area just offshore plunges to great depths just a few kilometers from land, hampering the use of fixed foundations, the most commonly used at present. However, the race to develop the technology of floating platforms that can sustain wind turbines, as an alternative to fixed foundations, is booming, providing an opportunity to develop offshore wind in Spain.

Floating platforms: benefits and characteristics

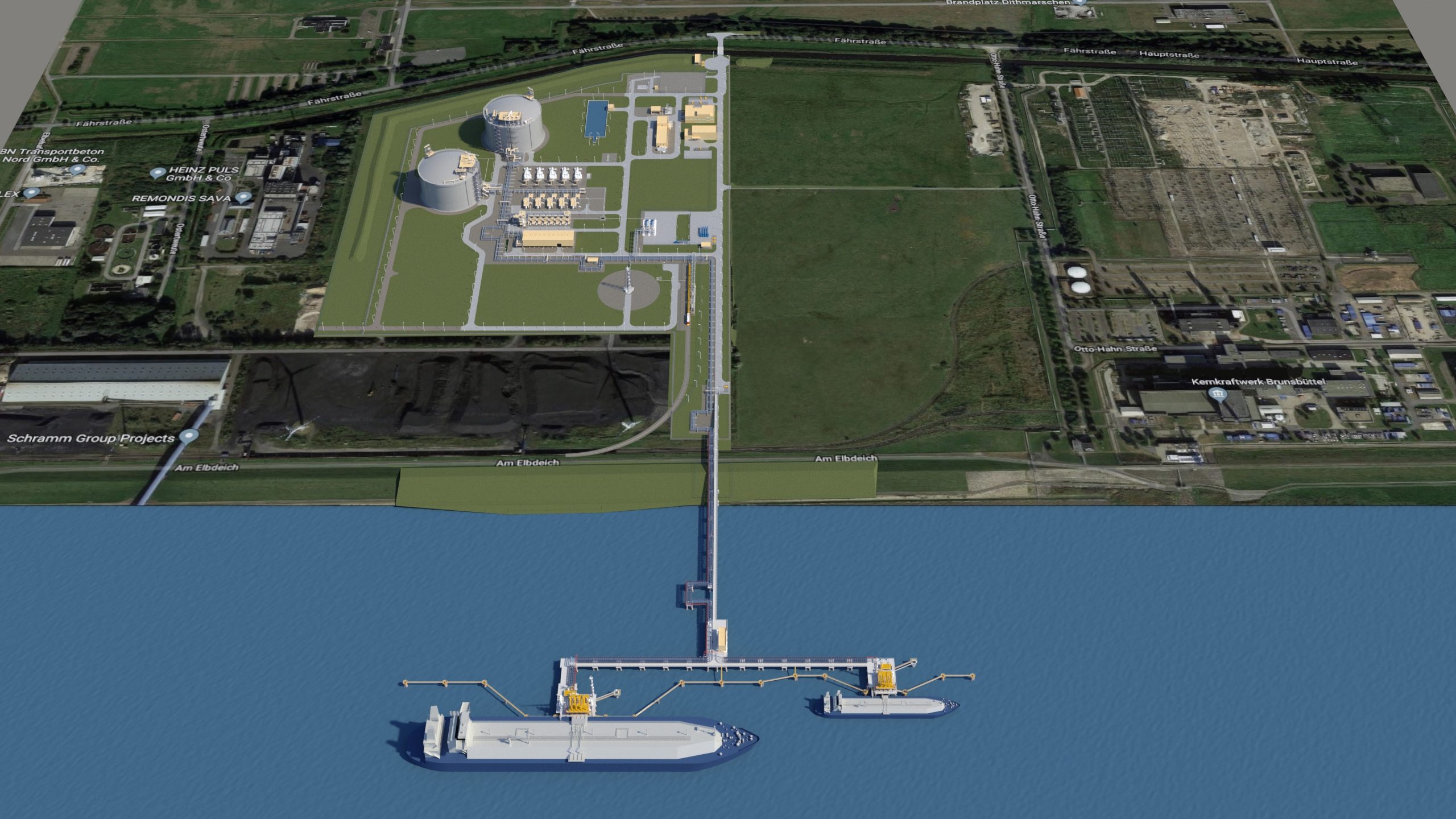

The design of these platforms, built out of steel, concrete or a combination of the two, varies widely in terms of geometry, weight, structural, buoyancy and stability properties, but they share the goal of trying to take advantage of being located in areas further away from the coast, where fixed foundations are inefficient from technical and economic points of view.

This is where solutions like the one proposed by Sener and Nervión Naval-Offshore, developers of HiveWind, a semi-submersible steel platform developed in Spain that can support high-power marine wind turbines (over 15 MW), come into play. Its design is intended to make it easier to manufacture and assemble the turbine, and ensure the high degree of standardization of its components. This standardization of components and the modularity of the solution allow it to be mass produced in different workshops and shipyards, while outsourcing and subcontracting certain components; this increases production capacity, promoting the local component in projects and thus reducing production times. These are all key aspects in a global market with high demand and a stressed supply chain.

Its design aims to emphasize modularity, standardization and reduced dimensions so it can be mass produced in shipyards. HiveWind stands out for its low weight, high performance and adaptability to different sites, making this a highly versatile solution. The HiveWind structure is made up of six hexagonal columns joined by arms in a parallelepiped shape at the bottom, creating the geometry of an equilateral triangle. The wind turbine is located in the central column of one of its sides, taking advantage of the outer columns of the vertices to brace the anchor lines and their connections to the floating platform itself.

The hallmark of HiveWind’s modular design is the repetition of elements all along the structure, which entails uniform thicknesses, towers and connecting arms between them. The flat panels that make up all these components result in the better use of the material, and make it easier to weld and to manipulate as needed later during assembly and construction. Its internal structure, both longitudinal and transverse, seeks to minimize the stresses to which each element will be subjected in different directions, thus avoiding high sheet thickness, which will result in a considerable reduction in the weight of the steel used in large areas of the platform.

HiveWind’s advantages are not only evident in terms of its structure or construction, but also in terms of its transportation, installation, operation and maintenance. The numerical models used to model and simulate the overall performance of the platform indicate that it is unnecessary to implement active ballast systems to ensure its static and dynamic stability, which simplifies and reduces the number of maintenance operations.

Another notable advantage of HiveWind is its low draft, meaning the wind turbine can be installed in more ports, making projects that rely on this solution more viable. In addition, tugs can transport the whole unit with the wind turbine to more ports of refuge, which provides a competitive advantage, especially in projects with very rough seas.

In short, the progress of the floating offshore wind power industry has reached a turning point in the search for sustainable energy solutions, with this system expected to play a prominent role in the energy mix. It is important to continue innovating and developing technology, such as HiveWind, to achieve this.

Miguel Taboada

A Naval Engineer from the Polytechnic University of Madrid with over 20 years of experience in the sector, he is also an associate professor at the School of Naval Engineering (UPM). My professional career has allowed me to specialize in the diverse aspects of the conceptual design of ocean-going vessels, including environmental conditions, stability, seakeeping analysis, mooring system design, physical model testing, and dynamic positioning (DP) systems.

About us

About us