- Energy

Categories:

Throughout history, waste management has been a constantly evolving sector marked by technological progress. It has shifted from a linear to a circular concept, compelling society to develop new ways to add value to waste—so much so that the term “waste” is gradually being replaced with “resources”.

After reduction and reuse, recycling remains the most effective method to recover materials found in waste and reintroduce them as raw materials for manufacturing new products. However, is it always possible to sort by material type, clean it, and reuse it? Or will chemical transformation of the base materials be necessary? This is particularly relevant in the case of plastic polymers. In their final commercial product form—such as a plastic bag or bottle—they often contain additives, dyes, or other materials, sometimes in simple forms and other times as multilayer or multi-material composites. Furthermore, the original properties of these products change during manufacturing, usage, and waste management, rendering them unsuitable for reuse in their original applications.

What can be done with plastic waste that cannot be mechanically recycled?

For a long time, the only options were landfill or incineration. But today, thanks to innovation, new alternatives are emerging, such as chemical recycling, which offers the potential to recover value from complex waste streams.

A brief history of plastic waste

Over the last century, rapid population growth—partly driven by technological advancement—has been accompanied by increased economic activity centred on consumer goods. These goods inevitably become waste at the end of their life cycle. With the rise of plastics like PVC, polyethylene or PET, and products such as Tetra Brik®, plastic waste generation has soared exponentially.

The widespread dispersion of plastics in the environment has become one of the greatest ecological challenges of our time. Plastics now litter oceans, beaches, and mountains, and awareness of their impact is steadily growing.

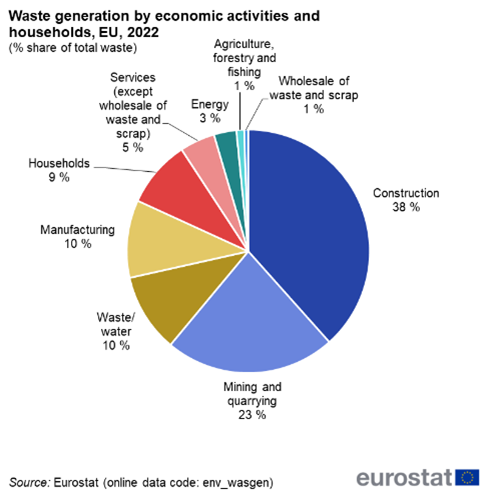

As citizens, we often assume that the household waste we generate represents the majority. Yet domestic waste only accounts for 9% of all waste produced in the European Union. It is therefore essential to also focus on industrial waste, which represents a vast source of potential resources and raw materials awaiting transformation and reintegration into the economic cycle.

Despite the progress made in recent decades, nearly half of all waste in the European Union still ends up in landfills or incinerators.

Beyond conventional recycling: emerging technologies

To make a qualitative leap in recycling performance, we must incorporate new technologies capable of processing currently unrecyclable waste. These include:

- Pyrolysis: breaks down plastics such as polyethylene or polypropylene into liquid hydrocarbons, which can be reused by the chemical industry.

- Gasification: converts carbon-rich waste into syngas, a valuable input for synthetic fuel production.

- Solvolysis: enables the breakdown of polymers such as polyurethanes or polyesters, recovering original components to produce new materials of equal quality.

Thanks to the momentum of decarbonisation and the circular economy, these technologies are now beginning to be deployed at industrial scale in Europe.

Sener’s contribution to chemical recycling

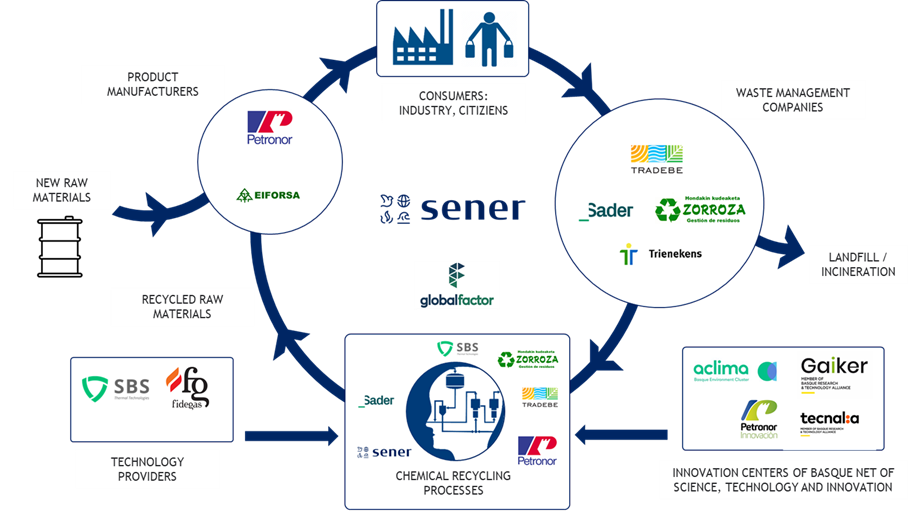

Sener is actively contributing to the development of chemical recycling through participation in the following projects:

- BIRPLAST: Research into the recovery and purification of new circular raw materials through separation processes and chemical recycling of plastic waste. The aim of the BIRPLAST Project is to generate a robust foundation of basic and technological knowledge to enable the development of chemical recycling technologies for difficult-to-recycle plastic waste, and to implement them in optimised, compact, flexible, reliable, high-efficiency, and economically viable process plants. BIRPLAST is funded by the Basque Government through the strategic HAZITEK programme for Industrial Research in the Circular Economy.

- WASTE2H2: Valorisation of plastic waste to produce hydrogen and other value-added products via deconstruction using new catalytic systems based on ionic liquids. The main objective of the WASTE2H2 project is to assess the feasibility and validate at laboratory scale (TRL4) a new disruptive solution centred on the development of innovative catalytic systems based on ionic liquids. When combined with microwave irradiation, these systems will selectively produce highly pure clean hydrogen and other valuable products from plastic waste. WASTE2H2 is funded by the European Union under the HORIZON-EIC-2023-PATHFINDER call: https://waste2-h2.eu/en.

Chemical recycling represents a necessary and complementary pathway to achieving sustainability and circular economy goals. Thanks to initiatives like BIRPLAST and WASTE2H2, technologies once limited to laboratories are becoming real, offering practical solutions to one of today’s most pressing environmental challenges: plastic waste.

This project has received funding from the European Union’s Horizon Europe research and innovation programme through the European Innovation Council under the grant agreement No. 101130249. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or European Innovation Council. Neither the European Union nor the granting authority can be held responsible for them.

Pablo Bernal

Chemical engineer with over 10 years of experience in the circular economy sector, managing a demonstration-scale technological innovation center for waste treatment processes. He is currently managing the BIRPLAST project as project manager and collaborating on engineering projects for biomethane plants using livestock and agro-industrial waste.