About us

About us About us / section

About us / section Markets

Markets Markets / section

Markets / section Careers

Careers Careers / section

Careers / section About us

About us About us / section

About us / section Markets

Markets Markets / section

Markets / section Careers

Careers Careers / section

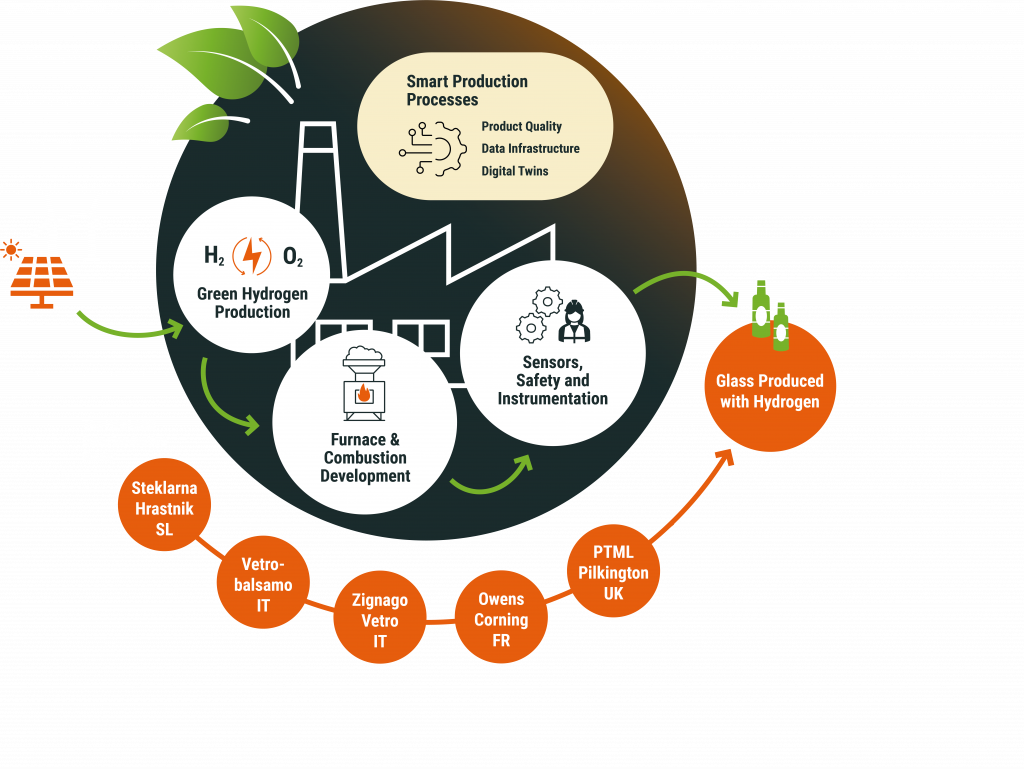

Careers / sectionThe efforts of electro-intensive industries to replace the use of fossil fuels with green hydrogen still face many challenges within the process: generating the hydrogen, preparing the infrastructure, modifying and adjusting the process, the economic viability and safe handling in industrial facilities.

H2Glass objective us to create a new technology stack that glass and aluminium manufacturers can use to achieve complete hydrogen combustion. Specifically, the project will address the challenges related to emissions of nitrogen oxides and high flame propagation speed, process efficiency and supply of hydrogen for on-site demonstrations. In addition, digital twin techniques will be used to assess risk-based predictive maintenance.

During the next 4 years full-scale tests will be carried out in European furnaces. Subsequently, the aim is to transfer the results of this research to all furnaces and achieve the total decarbonization of the glass industry in the next 30 years.

Additionally, to ensure safety throughout the project and to study the specific risks associated with the use of hydrogen (H2) in the glass and aluminum industry, the work includes several key objectives:

The project also encompasses the creation, development, and monitoring of a safety plan, along with the risk assessment for H2 applications in these industries.

funding from Horizon Europe

partners

Industrial demonstrators

Countries involved

Sener participates in H2Glass sharing the experience and technological knowledge of its expert team in the field of hydrogen to define and design a suitable and safe solution that integrates renewable hydrogen in the glass and aluminum production processes. In addition, we support the technology integration process in the different sites that are part of the project.

ASTON University, CIB UNIGAS, European Aluminium, Fraunhofer, Hydro Havrand, National Institute of Chemistry, Norwegian University of Science and Technology, Owens Corning, PTML Pilkington, Sener, SINTEF Manufacturing, Stazione Sperimentale del Vetro, STAM, Stara Glass, Steinbeis Europa Zentrum, Steklarna Hrastnik, Technical University of Catalonia,University of Nottingham, Vetrobalsamo, we, Zignago Vetro.