- Energy

- Innovation

- Digitalization

Categories:

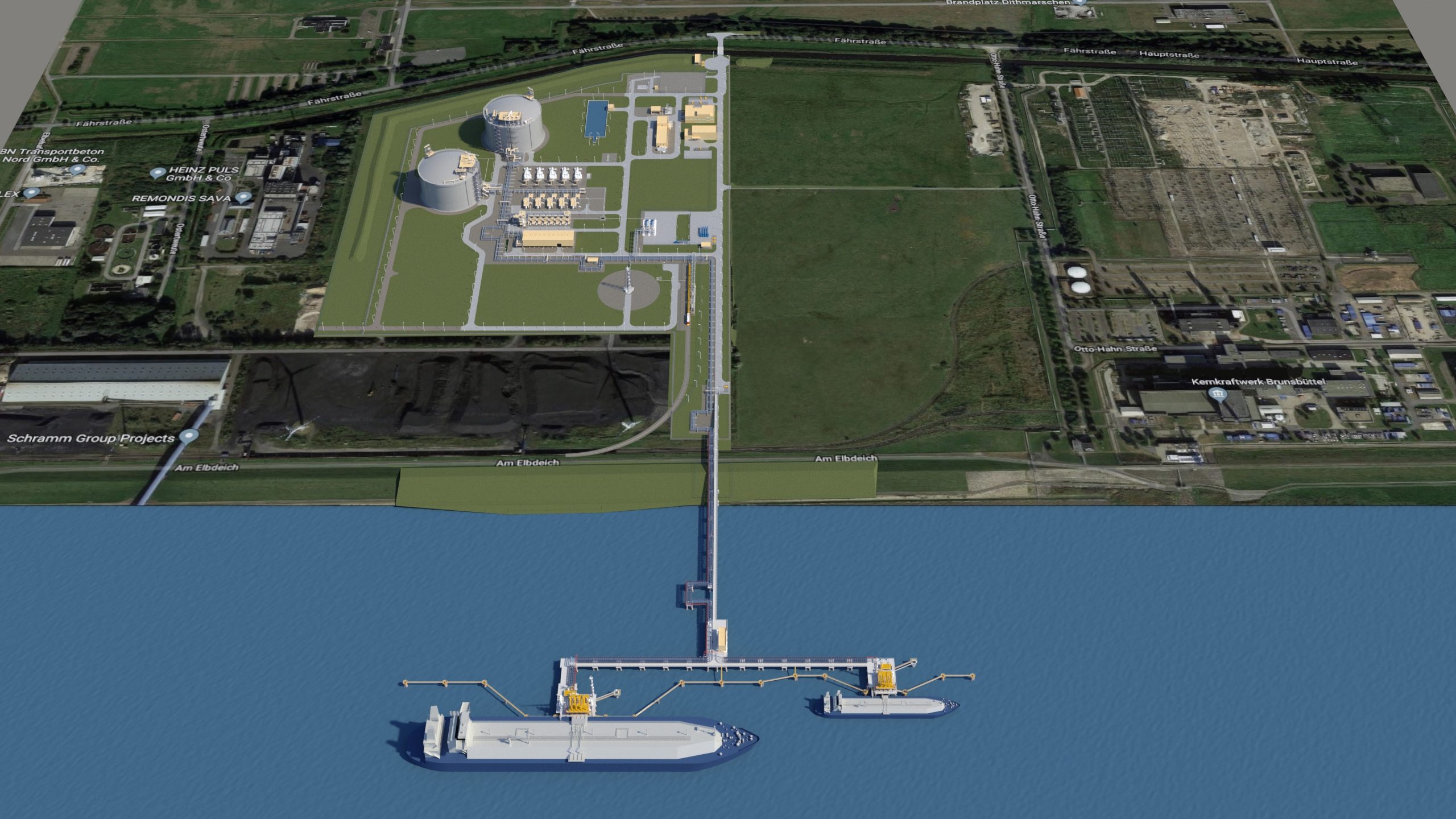

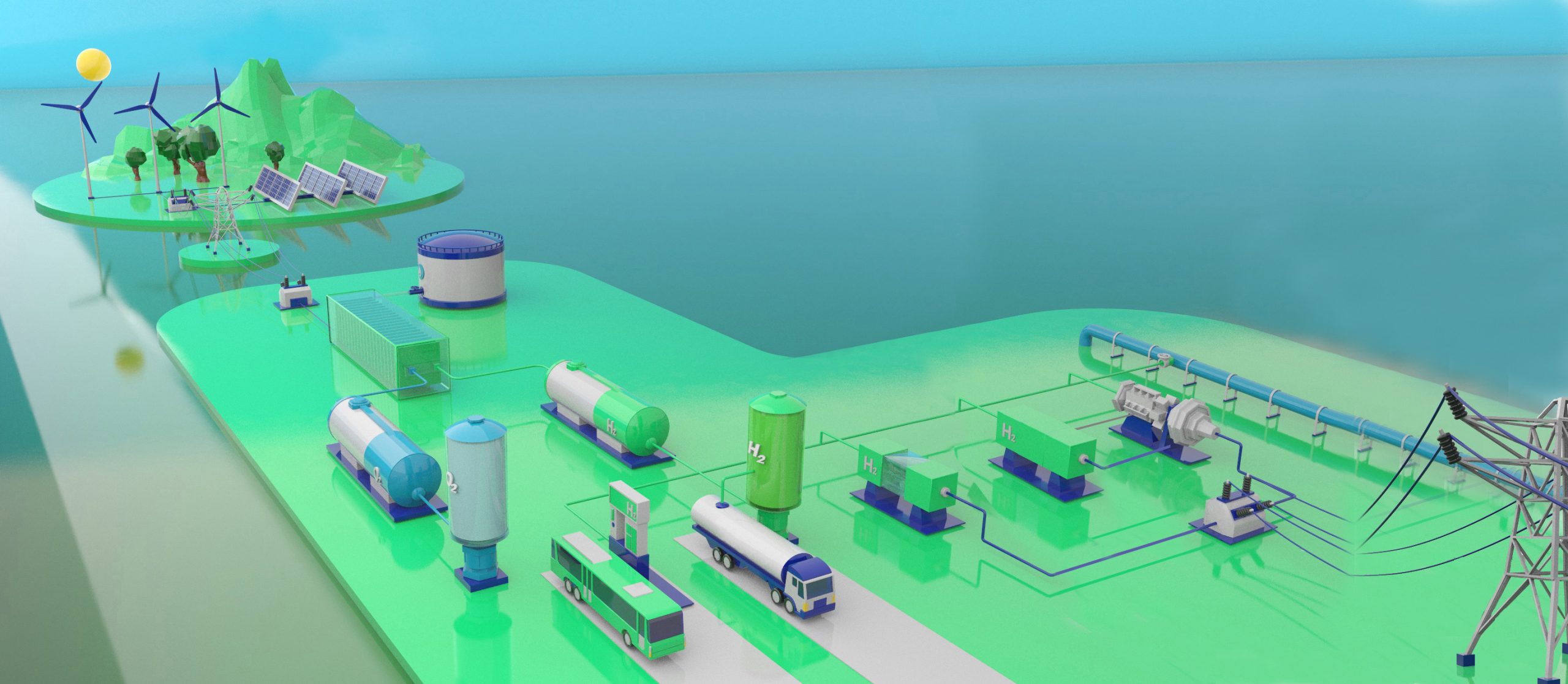

Green hydrogen – meaning hydrogen that has been obtained without generating polluting emissions – is shaping up to be a key energy vector on the road to decarbonization. Which is why taking the step toward industrializing the process of producing this type of hydrogen has become a priority for both public institutions and private entities. Although gray hydrogen is still much cheaper to produce than green, or sustainable, hydrogen, we are being presented a new window of opportunity thanks to the drop in the price of renewable energies and the policies being planned to boost their development.

Electrolyzers, which are essential elements in the process of generating green hydrogen, are constantly evolving and their development will be crucial for making this technology economically viable. Development times and their optimization will be key to the success or failure of the process.

Fortunately, we have technological levers that will help us drive the process, speed it up and guarantee its success. Digitization, simulation and artificial intelligence (AI) are the elements that will allow us to use the operating data – not only from the equipment, but also from all the environmental variables and manufacturing processes – from the first facilities that go online in order to improve the performance of the equipment and reduce manufacturing times and costs.

“Digitization and AI will play a prominent role in managing energy production and storage based on demand and market price, with hydrogen as a key element for managing electricity due to its ability to be used both as energy storage and fuel for mobility.”

The industrial production of green hydrogen comes at the perfect time to grow into a smart, digitized industry from the outset, one that makes it possible to achieve management, sustainability and reduced operating cost objectives for generating this type of energy, the main focus of the imminent energy transformation. Turning green hydrogen into a viable alternative.

To achieve this, green hydrogen production plants should be designed and built using BIM methodology, and the equipment and processes associated with these facilities must be digitized so they can provide value throughout the life of the plants. The concept of digital twin will be established as a connecting element of all the processes associated with an industrial production facility: from its design, detailed engineering, purchasing and start-up, to its operation and maintenance (including simulations) and finally its decommissioning. All the information on equipment and processes can be logged and exploited to generate value, speed up processes and maximize and ensure the economic return of the facilities. In turn, different solutions may be proposed for the predictive maintenance of the equipment and to determine operational actions, both to supervise the plant in real time and those associated with the strategies of the facility’s operator.

Digitization and artificial intelligence will play a prominent role in managing energy production and storage based on demand and market price, with hydrogen as a key element for managing electricity due to its ability to be used both as energy storage and fuel for mobility. In the medium term, these facilities will need to have secure data integration and exchange capabilities, which will be essential to enable the effective and efficient management of the grid.

- H2

Tags:

Iñaki Mendicute

Ingeniero de soluciones digitales en Sener

Ingeniero de Telecomunicaciones por la Escuela Técnica Superior de Ingeniería de la Universidad del País Vasco. Iñaki cuenta con más de 10 años de experiencia en el desarrollo e implementación de soluciones para el soporte de la Operación y Mantenimiento en diferentes sectores e industrias. Ha participado en proyectos en el ámbito de la energía, las energías renovables, el sector del Food and Beverage o la logística.

About us

About us