- Energy

Categories:

As an energy vector, green hydrogen (extracted from renewable sources) provides a means to store clean energy and release it when and where it is needed. But “green” isn’t its only color: this term describes its origin, while pink hydrogen, for example, is generated through electrolysis powered by nuclear energy, and blue hydrogen is sourced from natural gas with CO2 emissions capture.

A large amount of hydrogen is currently produced from hydrocarbons, which makes it a source of greenhouse gas emissions. Incorporating CO2 capture into conventional processes could reduce emissions by as much as 90%, facilitating the transition to hydrogen production with low carbon emissions, i.e., blue hydrogen.

However, blue hydrogen is not a 100% renewable alternative, so it is not a viable long-term solution. Therefore, if we want to promote the use of hydrogen to meet the current decarbonization targets, we must focus on developing an industry that is capable of producing green hydrogen through electrolysis or another technology that avoids CO2 emissions.

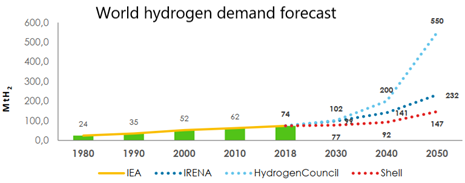

All the forecasts point to a growth in global hydrogen demand in the medium (2030) and long term (2050), but with significant differences between sources: no one can anticipate its future exactly due to complex market dynamics, such as the appearance of new uses and consumption models.

In coming decades, new applications are expected to drive the demand for hydrogen, which the most ambitious predictions say could expand growth 7.5-fold by 2050.

In coming decades, new applications are expected to drive the demand for hydrogen, which the most ambitious predictions say could expand growth 7.5-fold by 2050.

Electrolysis: the most widespread option for generation, a potential game-changer for European industry

Due to its versatility and scalability, hydrogen could mark a turning point in the decarbonization of the entire economy, especially in sectors where this goal is more challenging. But it can also boost the development of Europe’s manufacturing industry.

The most widespread production method today, due to its functionality and feasibility, is electrolysis, which uses electricity to dissociate, or separate, the water molecule into oxygen and hydrogen. The current electrolyzer technologies are in an early stage of industrial development, which poses both a challenge and an opportunity to make hydrogen more competitive and develop a powerful European value chain for hydrogen.

In Sener’s case, we recently worked in this area with the construction of a hydrogen generation plant with a 2.5 MW electrolyzer for the Petronor refinery in Muskiz. This electrolyzer will supply the Basque Hydrogen Corridor to generate the first renewable hydrogen in the Basque Country.

To meet the targets set by Europe, we must increase the manufacturing capacity of these systems. To date, more than 70 GW of electrolysis capacity has been announced for 2030, with over 80% of the projects located in Europe, and the number of projects announced has increased substantially year after year.

Is hydrogen competitive?

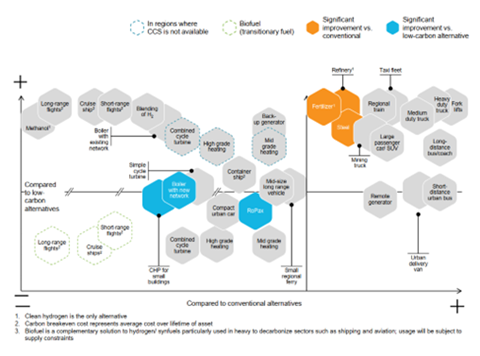

The price of hydrogen is expected to fall to within the 1.6 to 2.3 American dollar a kilo range by 2030. With no emissions costs, it would be competitive, primarily for heavy-duty road transportation (excluding cars). Other forms of transportation (such as maritime or aviation) are even further away from this break-even point with conventional fuels.

To be more competitive, we must take into account both the cost of emissions and the lower cost of producing hydrogen. This makes the latter a more viable option in industrial applications, such as the manufacture of steel or fertilizers, or in refineries, where the cost of carbon emissions could come to around 100 American dollars per ton of CO2 equivalent. In other sectors such as aviation, marine transport and heating, hydrogen will have to compete with other decarbonization alternatives, such as biofuels.

Present and future applications: Sener’s strategic plan

To address the different sectors where hydrogen may be competitive, Sener has drawn up a strategic R&D plan with two areas of work:

- We are already working on the first one, which involves optimizing existing alkaline electrolyzer solutions from a global perspective and adapting them to uses of hydrogen that we are anticipating, as we seek to scale the different systems to become more competitive without sacrificing the operational efficiency and flexibility that will be required to supply electrolyzers from renewable generation.

- The second one has as its aim to develop a new generation of electrolyzers with in-house technology that adapts not only to the current uses of hydrogen, but also to future uses starting in 2025,

The European Commission has identified this R&D project as an “Important Project of Common European Interest,” financing it through the IPCEI Hy2Tech program.

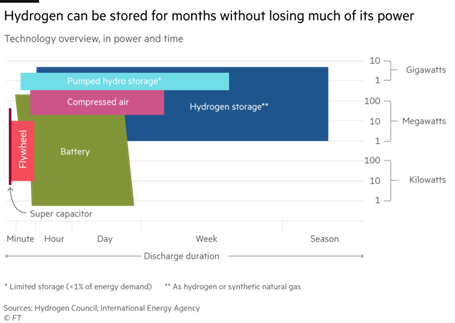

Also worth noting is hydrogen’s great potential in the field of energy storage to overcome one of the main barriers of renewable sources, such as wind and solar: availability.

In addition, lithium-ion batteries (which now supply 99% of all new storage capacity) are less economically competitive as the storage time increases, which makes it necessary to look for alternatives that offer stability to the grid over time periods of hours to weeks in order to match supply and demand.

Hydrogen storage can perform this function. Between 2050 and 2070, hydrogen with up to two weeks of stored energy is expected to provide a cost-effective storage method, depending on the capital costs of power and electricity capacity.

Moreover, since hydrogen can be used in other sectors, such as transportation and industry, it could provide additional revenue streams, which could be key to the profitability of seasonal hydrogen storage.

Given its potential, Sener is committed to green hydrogen as a vehicle for decarbonization as part of the mix of renewables that will make this possible. In addition to the aforementioned projects, we are part of the Basque Hydrogen Corridor, the Hydrogen Corridor of the Ebro Valley and the European Alliance for Clean Hydrogen. In coming decades, we will see more decisive industrial applications if research and development projects confirm what the predictions are indicating.

- green-hydrogen

- hydrogen

Tags:

Nora Castañeda

Hydrogen Business Manager

More than 20 years of experience creating innovative engineering solutions, executing turnkey projects, seeking alliances and creating new businesses, fundamentally in the world of Energy, focusing on renewable and sustainable responses, hybridizing technologies and pioneering ideas.

About us

About us