- Energy

Categories:

Industrial decarbonisation is key to achieving carbon neutrality targets by 2050. Sectors with high emissions must assess and possibly combine various strategies and technologies, from energy efficiency and electrification to carbon capture and alternative fuels. A comprehensive approach supported by specialised engineering is essential to designing cost-effective and economically viable roadmaps.

European context

The industry faces a context of increasing uncertainty, marked by the volatility of energy markets, the evolution of environmental regulations and pressure to reduce emissions without compromising competitiveness. Accordingly, the European Union is promoting measures to reduce bureaucracy and streamline the implementation of clean technologies.

The European Union recently presented the Clean Industrial Deal with the aim of strengthening the competitiveness and resilience of the European industry, accelerating its decarbonisation and guaranteeing a sustainable future for the sector. The proposed measures include:

- Investing in clean technologies: The plan is to mobilise more than €100 billion to support the manufacture of clean technologies in Europe, including the creation of an Industrial Decarbonisation Bank.

- Regulatory simplification: Reduction of the bureaucratic burden for companies, especially small and medium-sized companies, by easing environmental reporting requirements and reconsidering recent corporate sustainability directives. Administrative charges related to sustainability and transparency in the supply chain are expected to be reduced by 25%, which could save European companies around €40 billion.

- Reduction of energy costs: Implementation of an Action Plan for Affordable Energy, with the aim of reducing energy bills for industries and consumers, promoting the use of renewable energies and improving energy efficiency.

- Flexibilisation of state aid: The European Commission proposes to make state aid rules more flexible and offer tax incentives to promote investments in clean technologies and decarbonisation, thus strengthening the competitiveness of the European industry.

The race towards Net Zero in the industry

Global commitment to carbon neutrality by 2050 requires a profound transformation in all economic sectors, and industry is no exception. Contributing approximately 30% of global CO2 emissions (according to the World Resources Institute), this sector faces the challenge of drastically reducing its carbon footprint without compromising its competitiveness or the security of energy supply.

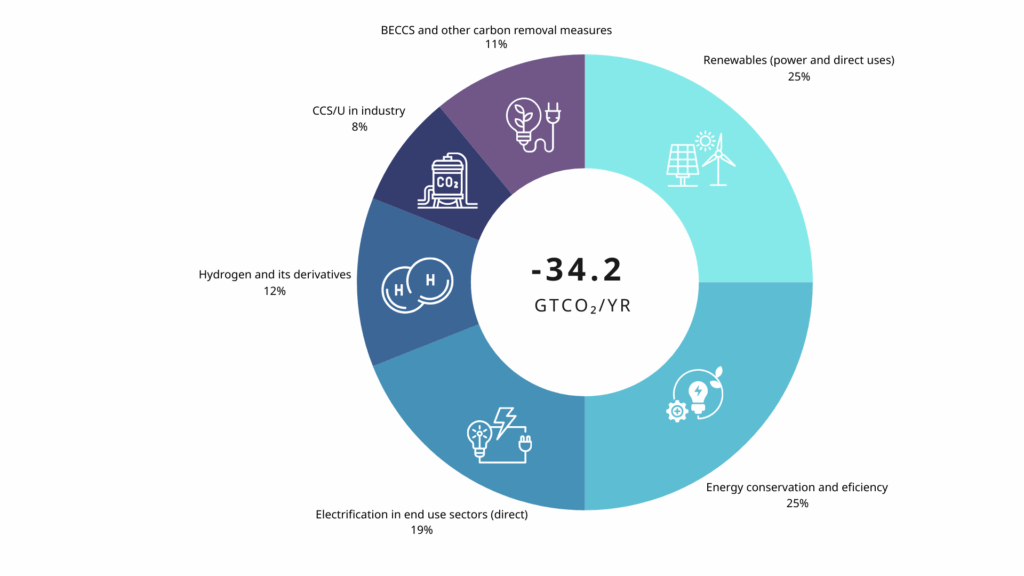

According to the International Renewable Energy Agency (IRENA), achieving the 1.5°C scenario by 2050 will depend on a combination of multiple technological strategies. As shown in the attached chart, renewable energies and energy efficiency will lead to a reduction in emissions, with 50% of the total contribution. Direct process electrification (19%) and the use of hydrogen and its derivatives (12%) will play a key role in replacing fossil fuels, while carbon capture, use and storage solutions (CCUS) and carbon bioenergy (BECCS) will be essential to mitigate residual emissions from sectors that are difficult to decarbonise.

This transition will not be achieved with isolated solutions but through a holistic approach that strategically integrates and adapts all these technologies to each industry. In this context, specialised engineering plays a fundamental role in providing the technical and economic expertise needed to design effective roadmaps towards decarbonisation.

Adapted from IRENA World Energy Transitions Outlook 2023: 1.5°C Pathway

Decarbonisation technologies: Complementary strategies

Industries should consider various technologies to reduce their carbon footprint. These solutions are not exclusive but complementary, and their application will depend on the characteristics of each production process.

- Energy Efficiency: The first step in any decarbonisation strategy is to optimise energy consumption, as explained in the EU’s Energy Efficiency First principle. Improving equipment efficiency, implementing advanced energy management systems and leveraging residual heat can significantly reduce fossil fuel consumption and, therefore, CO2 emissions.

- Renewable Generation: The integration of renewable energy sources, such as solar photovoltaic, wind and geothermal energy, is essential to reducing the dependence on fossil fuels in the industry. These solutions enable production processes to be powered by clean energy, significantly reducing carbon emissions. On the other hand, the rapid cost reduction and the increase in solar and wind energy efficiency, together with the advances in energy storage, have led to increasing competitiveness of renewable energies compared to traditional energy sources.

- Process Electrification: Replacing fossil fuel-based equipment with electric alternatives is an effective strategy in sectors where feasible, especially if the electricity comes from renewable sources. Technologies such as industrial heat pumps, electric ovens and electromagnetic induction can play a key role.

- Alternative Fuels: For processes where electrification is not viable, low-carbon fuels such as green hydrogen, biogas, sustainable biomass and even renewable synthetic fuels should be considered. The adoption of alternative fuels will depend on factors such as local availability and economic competitiveness compared to traditional fuels.

- Carbon Capture, Use and Storage (CCUS): In sectors where CO2 emissions are an intrinsic part of the process (e.g. cement and chemical production), carbon capture is an essential option. Technologies such as chemical absorption, adsorption and membrane capture can produce significant reductions in emissions in these processes.

Towards effective decarbonisation

While each technology has something to offer, the key to effective decarbonisation lies in a holistic approach. In other words, rather than implementing isolated technological solutions, the aim is to develop a roadmap that outlines the optimal integration of all available options at the appropriate time. This approach requires:

- Technical and Economic Analysis: Identifying the most viable solutions for each industrial plant based on criteria such as investment cost, economic return and technological maturity.

- Energy Infrastructure Assessment: Considering the capabilities of the electricity network, the infrastructure for supplying hydrogen or biogas, and the possibilities of integration with renewable energies.

- Flexibility and Adaptability: The energy transition is an evolving process. Industries must develop strategies that can adapt to regulatory, technological and market changes.

The decarbonisation of the industry is not a challenge that can be solved with a single, one-step solution but rather a process that requires the intelligent combination of multiple strategies, which must be carefully assessed to establish an effective roadmap. Energy efficiency, renewable generation, electrification, alternative fuels and carbon capture must be analysed together as part of a roadmap tailored to each case. Having expert and global insight enables industrial companies to make informed decisions, minimise risk and move effectively towards carbon neutrality. With this in mind, specialised engineering companies are positioning themselves as strategic allies to turn challenges into opportunities for sustainable transformation.

Sustainable Industry Business Line, Sener