- Mobility & Infrastructures

Categories:

Photograph: EPC Dunkerque LNG. Sea water intake

Hydraulics has experienced a significant evolution in the techniques used to calculate and obtain the maximum and minimum pressures in pressurized water pipes. For example, the Allievi method – developed at the beginning of the 20th century – provides a reasonable estimate, but it is limited, since it does not consider factors such as friction and temporal variation of pressures, making it not a suitable method to respond to the multitude of different scenarios that current use cases require.

The digitalization of the sector paved the ground for new techniques and tools to be developed in recent years that allow partial differential equations to be solved and thus represent the behavior of the fluid inside the pipe, improving aspects such as the way of representing the results, the way of considering with precision the real conditions of the piping system (including friction and temporal and spatial variations in pressures), the ability to solve mesh networks, the possibility of modeling elements to mitigate the effects of transients or the availability of calibrated libraries of the existing elements on the market (valves of all types, elbows, pump curves, etc.).

Currently, to ensure efficient and safe operation when designing and operating pressure piping systems, it is important to consider various situations that can generate transients in pressure piping and that must be analyzed to ensure their correct use. These situations are mainly based on the following phenomena:

- Flow variations over time (Q(t)): These can be caused by maneuvers in pumping stations, such as programmed start/stop or by power outage and variations in rotation speed. It can lead to unexpected overpressures or depressions that cause cavitation problems.

- Valve/hydrant maneuvers: The speed of these maneuvers can be controlled by the user.

Limitations of numerical models in hydraulic engineering

Numerical models, although a powerful tool in hydraulic engineering, are also limited. Such limitations must be considered by the designer and the modeling experience:

- Accuracy of input data: Numerical models are only as accurate as their input data.

- Computational complexity: Balance the computational complexity of the hydraulic model with the focus and uncertainties that we want to clear up in the design of the pressure network.

- Need for experience: Correctly interpreting the results of a numerical model requires a solid understanding of hydraulics and fluid mechanics. Without this experience, model results may be misinterpreted.

- Simplifying assumptions: Although numerical models can handle a wide range of conditions, they are often based on simplifying assumptions. For example, they may assume that the flow is completely turbulent or that the pipe walls are completely smooth.

Each system is unique, so specific solutions may vary depending on the characteristics of the system. In this sense, the experiences in countermeasures designed by the Water Technologies team at Sener cover a wide range of needs and are mainly based on:

- Valve speed control: Closing or opening a valve too quickly can cause transients. Controlling the speed at which the valves close or open limits the possibility of transients to allowable ranges.

- Use of pressure relief devices: These devices can release or admit water into the system to counteract rapid pressure changes.

- Use of air tanks or air chambers: These can provide cushion against pressure changes by allowing a certain amount of compression or expansion of the air within the tank.

- Proper system design: Careful system design, including proper location and sizing of pipes and pumps, can help minimize the effects of transients.

- Careful operation of the system: The preparation of a correct operation manual and a HAZOP analysis will define the maneuvers to consider in the operation of a pressure pipeline and in its allowable pressure range.

- Regular system maintenance: Proper maintenance can help prevent failures that could cause transients, such as leaks or valve failures.

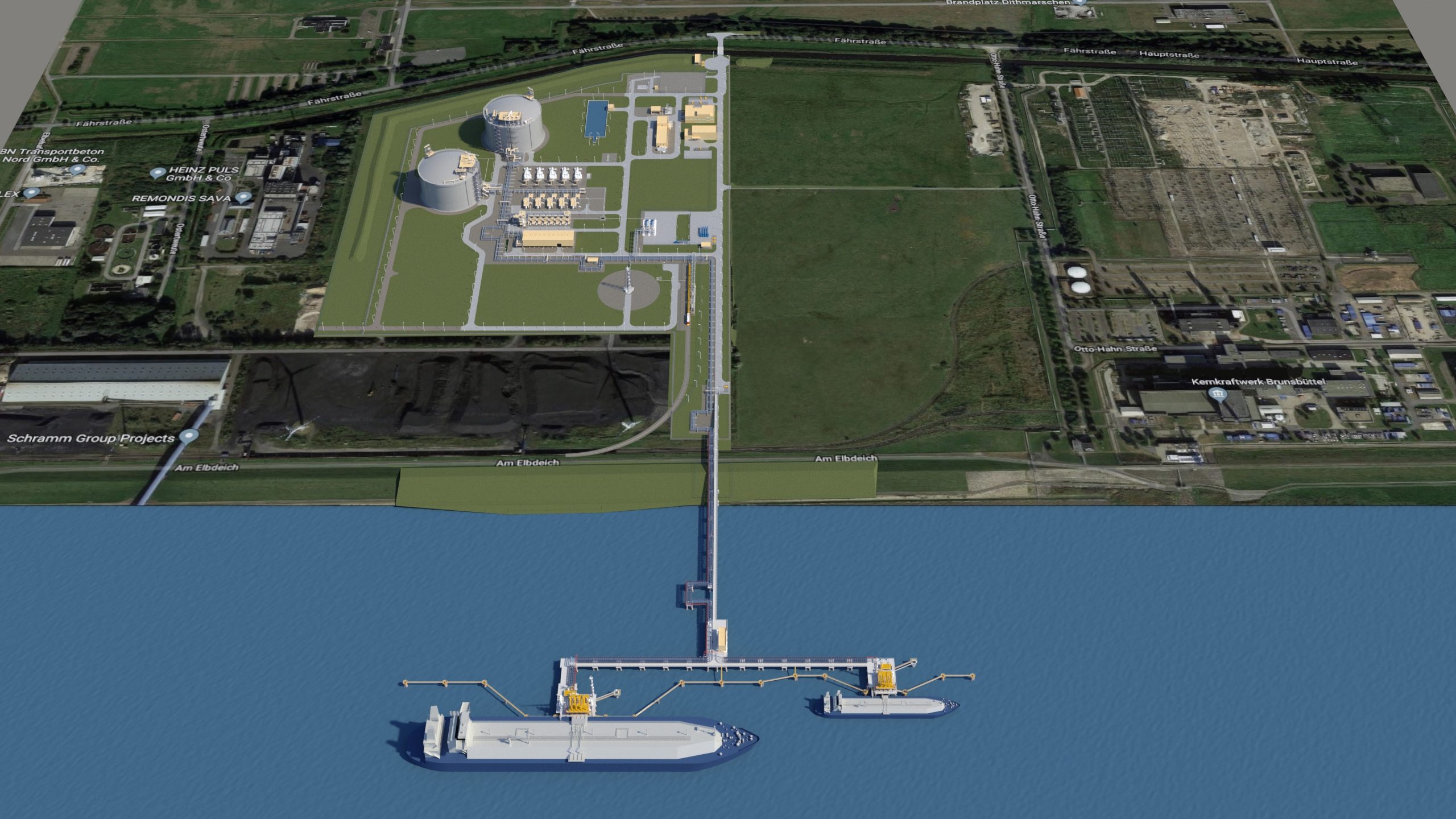

The evolution of calculation techniques is allowing the design of more efficient and safe pipelines, minimizing investment in countermeasures to limit the effects of transients, as demonstrated by recent success stories such as Gate Terminal, one of the largest liquefied natural gas terminals in Europe.

- digitalization

- water

- Pipes

Tags:

Iván Collado

Ivan Collado es ingeniero de caminos, especializado en obras hidráulicas y BIM Manager en ingeniería civil. Cuenta con 18 años de experiencia, todos ellos, en Sener, trabajando en estudios en el campo de la planificación u obra e infraestructura hidráulicas, asociados a otros proyectos diversos. En el campo industrial, ha participado en proyectos vinculados a sistemas de refrigeración de plantas energéticas, abarcando sus obras de captación, transporte, vertido y análisis de transitorios.

About us

About us