The H2SKID project has officially begun, aiming to develop a 1.25 MW experimental portable electrolyser with AEM/PEM technology. It is conceived as an enabling solution to supply green hydrogen to industrial end users.

With Sener’s participation and led by SARRALLE as coordinating entity, the project brings together eleven leading companies from across the hydrogen value chain. It is a unique initiative in the Basque Country, designed to drive industrial decarbonisation. In Sener’s case, and thanks to its previous R&D experience, the company will focus on designing the electrolyser’s main components. Sener has previously worked on next‑generation electrolysis technology development.

In the Basque Country, renewable hydrogen has become one of the strategic levers for advancing the decarbonisation of industry. Among the most promising pathways is the gradual substitution of natural gas with green hydrogen in high‑temperature processes, such as those in steelmaking, foundries, the paper industry, glass, cement and petrochemicals. However, for this transition to be viable, it is essential to ensure sufficient hydrogen supply to enable demonstrative tests under real operating conditions. At present, the lack of pipeline infrastructure connecting industrial facilities with centralised green hydrogen production plants limits such trials.

The H2SKID project has been created to address this need. Its objective is to design and build a portable, containerised electrolyser that will serve as an enabling solution for supplying green hydrogen to industrial end users. This infrastructure will allow long‑duration testing campaigns, which are essential to validate the performance of hydrogen‑fuelled industrial equipment. The project also includes advanced research into key electrolyser technologies and auxiliary systems, to strengthen a robust and competitive hydrogen production value chain.

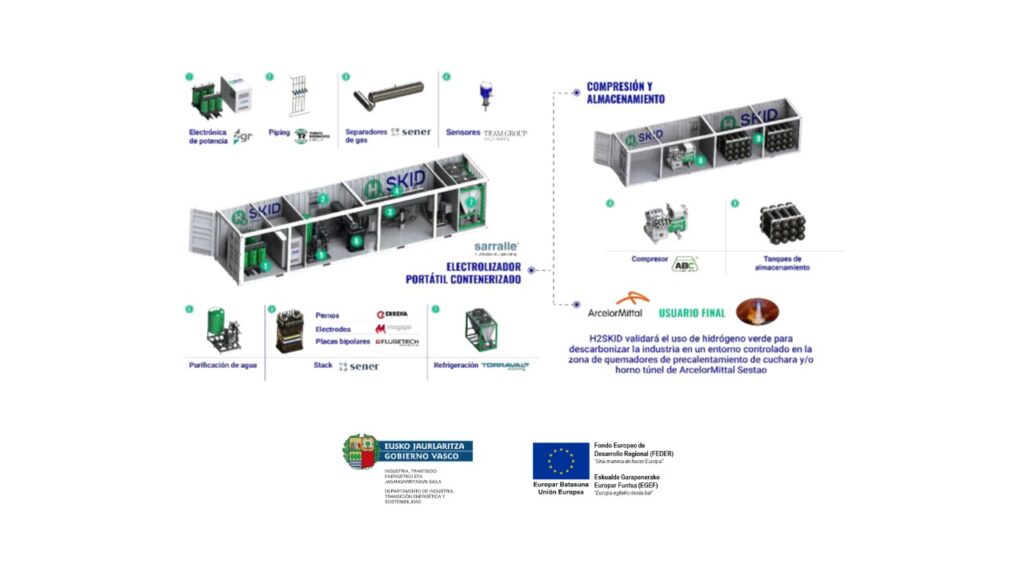

The H2SKID electrolyser is conceived as a compact, modular and plug‑and‑play experimental platform, integrated into two containerised modules: one dedicated to hydrogen production via electrolysis, and the other to compression and storage. The solution will be compatible with both AEM and PEM electrolysis technologies, offering high technological flexibility. In addition, the system will function as a test bench for the validation of critical components of both the electrolyser and the compressor.

The H2SKID solution will be validated in a real industrial environment, specifically in the ladle pre‑heating burner area and/or the tunnel furnace at ArcelorMittal Sestao, ensuring the practical relevance of the results obtained.

By the end of the project, H2SKID will have been consolidated as a flagship scientific‑technological tool to support the development of the hydrogen sector in the Basque Country and to accelerate industrial decarbonisation. H2SKID is a multi‑year (2025–2027) strategic industrial research collaboration involving the following entities: Sarralle (coordinator), ABC Compresores, ArcelorMittal Sestao, Erreka, Flubetech, Mugape, Sener, Team Group Engineering, Torraval, Tubos Reunidos Group and Zigor. It is also supported by ABC Tech, Tecnalia and Zigor’s R&D unit as members of the Basque Network of Science, Technology and Innovation (RVCTI), and by the BASQUE ENERGY Cluster for communication and dissemination activities.

H2SKID is funded by the Basque Government’s Department of Industry, Energy Transition and Sustainability (HAZITEK 2025 Programme) and by the European Regional Development Fund (ERDF 2021–2027).